Department of Engineering and Communication

Industrial robotics

Campus

Sankt Augustin

Room

B 014

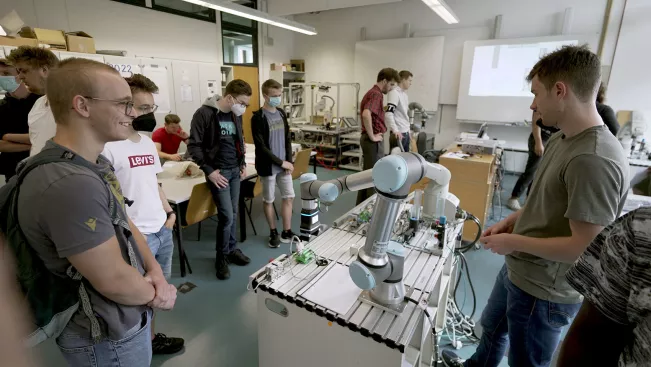

In the industrial robotics laboratory, students are trained on industry-related annexes. In addition to practical courses, interdisciplinary projects are also carried out, which often build on the results of previous projects.

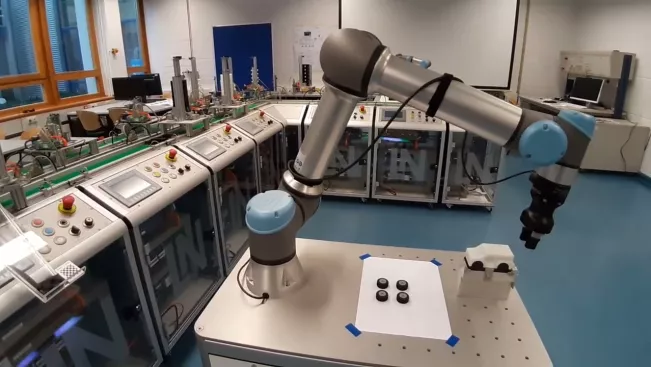

The laboratory has the following equipment, among others:

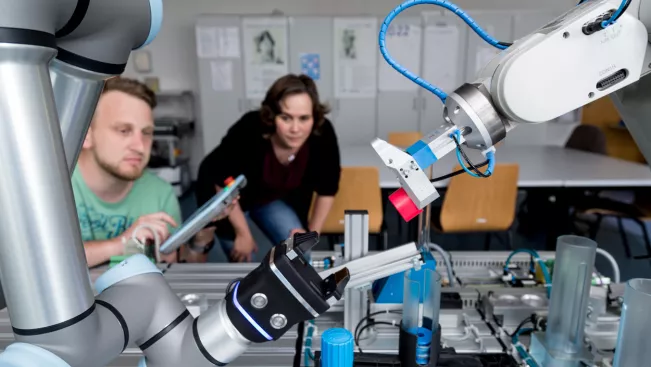

- Collaborative robot (Cobot) UR5e from Universal Robots with "Wrist Camera" from Robotiq

- Autonomous Mobile Robot (AMR) type MiR100 with permanently mounted cobot (UR5e) including "Wrist Camera" and electric two-jaw gripper

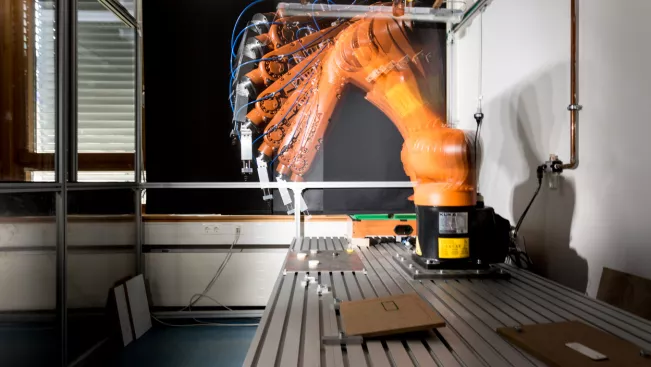

- 6-axis articulated arm robot withaxis articulated robot KR6 R900 sixx from KUKA

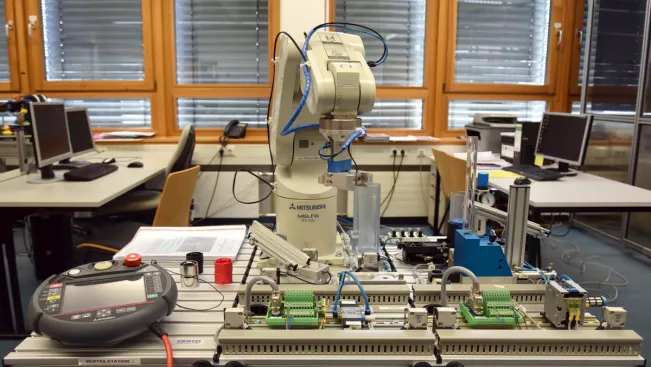

- 4-axis SCARA robot RH-6SDH from Mitsubishi

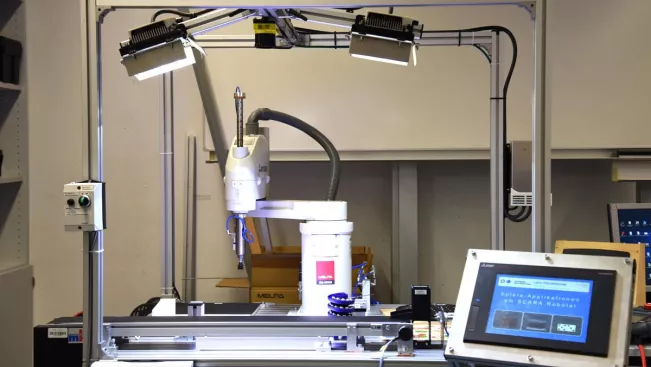

- 5-axis articulated robot RH-6SDH from Mitsubishi

- 6-axis articulated robot RV-1A from Mitsubishi

- Diverse in-Sight image processing systems from Cognex

- BCN3D Moveo (5-axis articulated arm robot) from Omron (formerly Adept)

- Software "CIROS" (offline robot programming and simulation system with cell modulation option and online connection to the real robot)Connection to the real robot)

The hardware is networked in an internal laboratory intranet via a switch, so that communication via Ethernet TCP/IP is possible between the PCs, industrial robots and image processing systems.

Internships

In the internships, students learn how to work with industrial robots and how to programme them.

We also use the CIROS software system for this purpose, which enables offline programming and simulation of the robot programme.

The students first work with the simulation to learn the programming language. The programme is then transferred to the real robot cell and can be put into operation there.

Learning how to programme and integrate an image processing system into a robot cell is also part of the practical training.

Projects

In the projects, the students are always given new practical assignments, which are systematically worked on in interdisciplinary teams using project management.

The assignments can include both software development and hardware design.

After the three project weeks have been completed, the results are documented and presented to other students.

The students are given the opportunity to work on their own projects

Project example: Wheel assembly in the "Smart Factory"

Small selection of project examples:

- Handling of components that enter a SCARA robot cell via a conveyor belt. The robot then sorts them using pattern recognition from a Cognex image processing system.

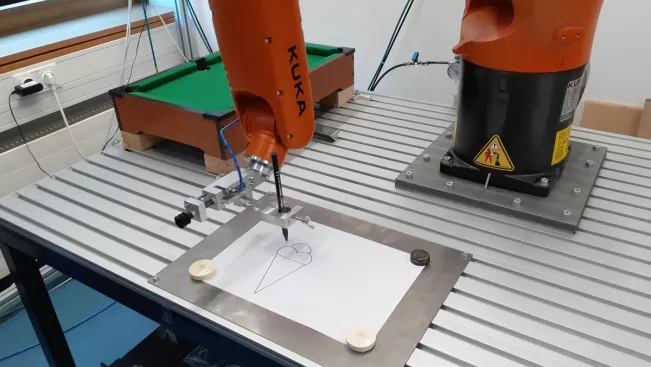

- Project planning and realisation of an application with a mini billiard game on a robot cell with a 6-axis vertical articulated arm robot from KUKA and an image processing system from Cognex.

- Integration of the Autonomous Mobile Robot into our "Smart Factory" to solve handling and assembly tasks.

- Programming of the collaborative robot in interaction with a 5-axis articulated robot to disassemble a previously assembled pneumatic cylinder.

- Construction and commissioning of new robot cells and their expansion.

Contact

Location

Sankt Augustin

Room

B 209

Address

Grantham-Allee 20

53757 Sankt Augustin

Telephone

+49 2241 865 359

Location

Sankt Augustin

Room

B 221

Address

Grantham-Allee 20

53757 Sankt Augustin

Telephone

+49 2241 865 366