real time curing and failure analysis of thermosets

Research project at a glance

Departments and Instituts

Funding type

Period

01.04.2015 to 31.12.2018

Project manager at H-BRS

Project Description

The construction of high quality polymer products, bondings and composite materials requires:

- wide knowlegde about the materials used

- reliable quality control for incoming and outgoing products

- high process safety

- reliable suppliers

Already for construction planing, proper materials have to be chosen. Not only the final price, but also the material properties such as the possible strain or influences by surrounding media have to be taken into account. In case the material fails during the fabrication, a lot of problems and costs may arrise. Material faliure may disturbe the whole construction process and even may influence subsequent orders, especially when productions runs 24/7 and "just in time". And this is where not only the source of failure, but also responsibilities has to be clarified. At this point, failure analysis can help to find which parameters led to the final material collapse. But which of the high variety of methods is the right one? How can I minimize the number of analyses and costs and get the fastest results? Aim of this Project is to teach strengths and weaknesses of the most important polymer analysis methods. The most common applications in terms of polymers, composite materials and adhesions are demonstrated with special respect for failure analysis and quality assurance.

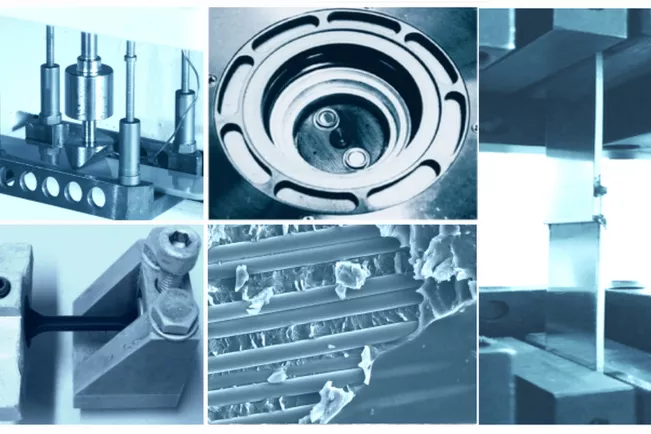

This includes the following analysis methods:

- Microscopic methods (light, digital and SEM)

- thermic analysis methods (DSC, DMA and DEA)

- mechanical analysis (static and dynamic)

- special polymer analysis methods (pyrolysis GC-MS, SPME-GC-MS, RFA, FT-IR, XRD, etc.)

Publications

-

L. Randolph, J. Steinhaus, B. Möginger, B. Gellez, J. Stansbury, W.M. Palin, G. Leloup, J.G. Leprince: Photopolymerization of highly filled dimethacrylate-based composites using Type I or Type II photoinitiators and varying co-monomer ratios. Dental Materials, (2015)

-

Kusch P, Obst V, Schroeder-Obst D, Fink W, Knupp G, Steinhaus J. Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries, Chapter 17 - Application of pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS) and scanning electron microscopy (SEM) in failure analysis for the identification of organic compounds in chemical, rubber, and automotive industry. Elsevier B.V., ISBN: 978-0-08-100116-5, (2015)

-

J. Steinhaus, B. Moeginger, M. Harrach, D. Guenther, F. Moegele, B. Hausnerova: Characterizing the Auto-curing Behaviour of Rapid Prototyping Materials for 3D-Printing via DEA, Polymer Engineering and Science, Vol. 55, Issue 7, p. 1485-1493, (2015)

-

T. Haenel, B. Hausnerová, J. Steinhaus, R.B.T. Price, B. Sullivan, B. Möginger: Effect of the irradiance distribution from light curing units on the local micro-hardness of the surface of dental resins, Dental Materials, Vol. 31, Issue 2, p. 93-104, (2015)

-

J. Steinhaus, B. Möginger, M. Grossgarten, M. Rosentritt, B. Hausnerova: Dielectric analysis of depth dependent curing behaviour of dental resin composites, Dental Materials, Vol. 30, Issue 6, p. 679-687, (2014)

-

J. Steinhaus, B. Hausnerova, T. Haenel, M. Großgarten, B. Möginger: Curing kinetics of visible light curing dental resin composites investigated by dielectric analysis (DEA), Dental Materials, Vol. 30, Issue 3, p. 372-380, (2014)

-

P. Kusch, G. Knupp, W. Fink, D. Schroeder-Obst, V. Obst, J. Steinhaus: Application of Pyrolysis-Gas Chromatography-Mass Spectrometry for the Identification of Polymeric Materials, LCGC North America, Vol. 32, No. 3, (2014)

-

A. M. Netto, J. Steinhaus, B. Hausnerova, B. Moeginger, B. Blümich: Time-Resolved Study of the Photo-Curing Process of Dental Resins with the NMR- MOUSE, Applied Magnetic Resonance, Vol. 44, 1027-1039, (2013)

-

P. Kusch, V. Obst, D. Schroeder-Obst, W. Fink, G. Knupp, J. Steinhaus: Application of pyrolysis-gas chromatography/mass spectrometry for the identification of polymeric materials in failure analysis in the automotive industry, Engineering Failure Analysis, Vol. 35, 114-124, (2013)

-

T. Haenel, R. B. T. Price, J. Steinhaus, B. Möginger, B. Hausnerova: Lichthärtende Dentalkomposite - Einflüsse auf die Aushärtung, ZWR - Das Deutsche Zahnärzteblatt, Vol. 122, 01/2013, 72-76, (2013)