Department of Natural Sciences

Prof. Dr Christian Dresbach

Professor for Materials Science, particularly structural and functional materials and simulation/Course guidance MSc Materials Science and Sustainability Methods

Unit

Department of Natural Sciences, Institute of Technology, Resource and Energy-efficient Engineering (TREE)

Location

Rheinbach

Room

I205

Address

von-Liebig-Str. 20

53359 Rheinbach

Profile

Lehrveranstaltungen

- Keramiken und Gläser

- Metalle und Legierungen

- Conventional Processing Techniques (part: metals & ceramics)

- Simulationsmethoden (Teil: FEM)

- Composites and Hybrid Structures (part: ceramic matrix composites)

- WPF Betriebsfestigkeit & Bruchmechanik

- WPF Werkstoffe der Luft- und Raumfahrt

Forschungsgebiete

- Zuverlässigkeit und Lebensdauer

- Parameteridentifikation und Optimierung

- Mechanische Charakterisierung in kleinen Dimensionen

Laborausstattung

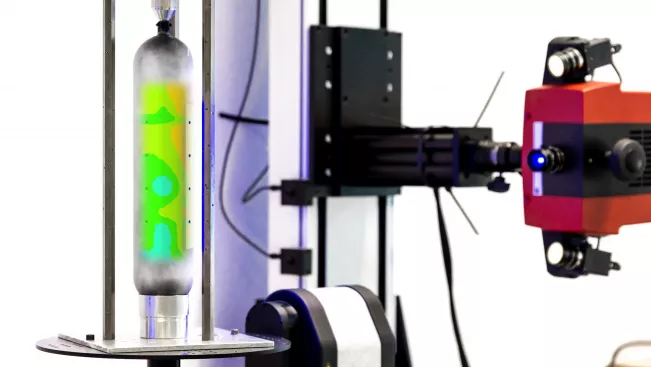

- Nanoindenter (gemeinsam genutzt)

- Impulserregungstechnik von RT bis 1500°C

- Universalprüfmaschine für kleine und mittlere Lasten (20N, 1kN, 10kN) mit Laserextensometer

- Multi-Kriech- und Relaxationsprüfstand (4 x 2,5kN + 1x 0,5kN) mit Temperiereinheit und Videoextensometer

- Elektrodynamische Prüfmaschine (100N, 1kN) mit Temperiereinheit

- Workstation für Finite Elemente Simulationen (Ansys) und Optimierungen (OptiSLang)

- Weitere Ausstattung des TREE-Forschungsfeldes Nachhaltige Materialien

Curriculum vitae

seit 2018 Professor für Materialwissenschaften, insbesondere Struktur- und Funktionswerkstoffe sowie Simulation

2010 - 2018 Wissenschaftlicher Mitarbeiter beim Deutschen Zentrum für Luft- und Raumfahrt, Institut für Werkstoff-Forschung in Köln

2004 - 2010 Mitarbeiter am Fraunhofer Institut für Werkstoffmechanik IWM in Halle (jetzt Fraunhofer IMWS) und Promotion an der Martin-Luther-Universität Halle-Wittenberg

2000 - 2004 Studium der Werkstofftechnik an der Fachhochschule Bonn-Rhein-Sieg

Research Projects

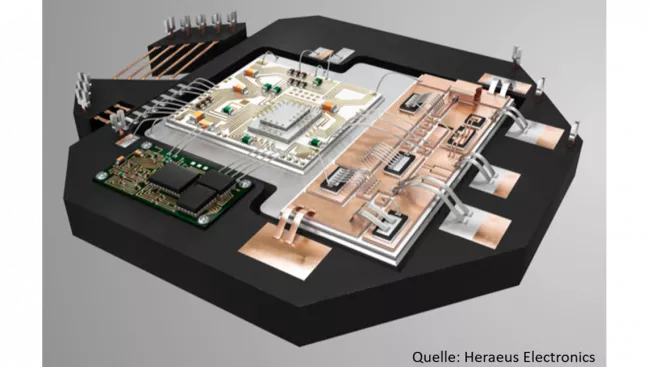

Wire or ribbon connections made of aluminum are usually used to transmit electrical power in control units and power electronics modules. Since the connection points of the wires and ribbons are usually located on substrates made of different materials and the components are frequently exposed to external temperature differences, cracks can form in the material during operation and lead to complete failure of the component, which cannot be remedied by simple design modifications.

Project management at the H-BRS

Prof. Dr Christian DresbachIn modern society, plastic packaging fulfills important functions for consumers and industry and is indispensable in everyday life: easy and inexpensive to produce in large quantities, it significantly simplifies handling during transport and storage and extends the shelf life of food up to three times.

Project management at the H-BRS

Prof. Dr Christian Dresbach Dr Esther van DorpPublications

2026

Julian Rech, Christian Dresbach, Esther Ramakers van Dorp, Bernhard Möginger, Berenika Hausnerova:

Towards reliable elastic characterization of glass bead reinforced thermoplastic composites using impulse excitation and conventional testing.

PDF Download (CC BY 4.0) doi:10.1038/s41598-026-36346-z PMID urn:nbn:de:hbz:1044-opus-94523

BibTeX | RIS

2025

Sebastian Möller, Dimitrios Nouskalis, Björn Ehmke, Holm Altenbach, Christian Dresbach:

Combined Influence of Stretch-Bending Straightening and Ageing on the Tensile Properties of Packaging Steels.

PDF Download (CC BY 4.0) doi:10.3390/met15080894 urn:nbn:de:hbz:1044-opus-91410

BibTeX | RIS

Michael Meurer, Gatien Kamsu Fogain, Esther Ramakers-van Dorp, Christian Dresbach, Bernhard Möginger, Berenika Hausnerova:

RheoTack evaluation of detaching behavior of silicone-based pressure sensitive adhesives for transdermal therapeutic systems.

doi:10.1016/j.measurement.2025.117436

BibTeX | RIS

2024

Sebastian Möller, Dimitrios Nouskalis, Björn Ehmke, Dirk Matusch, Christian Dresbach, Holm Altenbach:

Effects of Stretch-Bending Straightening on the Tensile Properties of Cold Rolled Packaging Steel.

PDF Download (CC BY 4.0) doi:10.3390/met14111203 urn:nbn:de:hbz:1044-opus-86383

BibTeX | RIS

2023

Cassandra Moers, Christian Dresbach, Holm Altenbach:

A Fatigue Lifetime Prediction Model for Aluminum Bonding Wires.

PDF Download (CC BY 4.0) doi:10.3390/met13101781 urn:nbn:de:hbz:1044-opus-75701

BibTeX | RIS

Patrick Michels, Christian Dresbach, Esther Ramakers-van Dorp, Holm Altenbach, Olaf Bruch:

Application of Nonlinear Viscoelastic Material Models for the Shrinkage and Warpage Analysis of Blow Molded Parts.

doi:10.1007/978-3-031-39070-8_13

BibTeX | RIS

Michael Meurer, Gatien Kamsu Fogain, Esther Ramakers van Dorp, Christian Dresbach, Bernhard Möginger, Berenika Hausnerova:

Rate dependent tack behavior of silicone-based pressure sensitive adhesives for transdermal therapeutic systems.

doi:10.21203/rs.3.rs-3010924/v1

BibTeX | RIS

2022

Cassandra Moers, Christian Dresbach:

Influence of R-Ratio on Fatigue of Aluminum Bonding Wires.

PDF Download (CC BY 4.0) doi:10.3390/met13010009 urn:nbn:de:hbz:1044-opus-65588

BibTeX | RIS

C. Dresbach, J. Wischek, M. Bartsch, T. Prien:

A small‐scale creep test for calibrating an efficient lifetime model for high pressure turbine blades.

PDF Download (CC BY-NC-ND 4.0) doi:10.1002/mawe.202100347 urn:nbn:de:hbz:1044-opus-61937

BibTeX | RIS

2020

Joachim Gussone, Katrin Bugelnig, Pere Barriobero-Vila, Julio Cesar da Silva, Ulrike Hecht, Christian Dresbach, Federico Sket, Peter Cloetens, Andreas Stark, Norbert Schell, Jan Haubrich, Guillermo Requena:

Ultrafine eutectic Ti-Fe-based alloys processed by additive manufacturing – A new candidate for high temperature applications.

PDF Download (CC BY-NC-ND 4.0) doi:10.1016/j.apmt.2020.100767 urn:nbn:de:hbz:1044-opus-50103

BibTeX | RIS

2017

Marinus Johannus van Enkhuizen, Christian Dresbach, Stefan Reh, Stefan Kuntzagk:

Efficient Lifetime Prediction of High Pressure Turbine Blades in Real Life Conditions.

doi:10.1115/GT2017-63341

BibTeX | RIS

2016

Clemens Buske, Alexander Krumme, Thomas Schmidt, Christian Dresbach, Sascha Zur, Rüdiger Tiefers:

Distributed Multidisciplinary Optimization of a Turbine Blade Regarding Performance, Reliability and Castability.

doi:10.1115/GT2016-56079

BibTeX | RIS

Christian Dresbach, Thomas Becker, Stefan Reh, Janine Wischek, Sascha Zur, Clemens Buske, Thomas Schmidt, Ruediger Tiefers:

A Stochastic Reliability Model for Application in a Multidisciplinary Optimization of a Low Pressure Turbine Blade Made of Titanium Aluminide.

doi:10.1590/1679-78252521

BibTeX | RIS

Thomas Becker, Christian Dresbach, Stefan Reh:

Adaption of a material model and development of a stochastic failure criterion for ceramic matrix composite structures.

doi:10.1177/1464420715592188

BibTeX | RIS

2014

Christian Dresbach, Marinus J. van Enkhuizen, Ulises Alfaro Mercado, Stefan Reh:

Simulation of thermal behavior during friction stir welding process for predicting residual stresses.

doi:10.1007/s13272-014-0145-9

BibTeX | RIS

C. Dresbach, U. Dressler, J. Gussone, S. Reh:

Calculation of effective Young's modulus distribution from electron backscatter diffraction results for stochastic analyses in aerospace applications.

doi:10.1002/mawe.201400235

BibTeX | RIS

2013

Marinus Johannus van Enkhuizen, Christian Dresbach, Stefan Reh:

Determining Local Material Properties via Inverse Parameter Identification of Instrumented Indentation Experiments.

BibTeX | RIS

2012

Holm Altenbach, Christian Dresbach, Matthias Petzold:

Characterizing the Anisotropic Hardening Behavior of Aluminum Bonding Wires.

doi:10.1007/978-3-642-22700-4_36

BibTeX | RIS

2011

Christian Dresbach, Georg Lorenz, Matthias Petzold, Holm Altenbach:

Analysis of Chip Damage Risk in Thermosonic Wire Bonding.

doi:10.4028/www.scientific.net/KEM.478.75

BibTeX | RIS

2010

G. Lorenz, M. Petzold, M. Mittag, C. Dresbach, E. Milke:

Mechanical characterization of gold and copper free air balls in thermosonic wire bond interconnections.

doi:10.1109/ESTC.2010.5642816

BibTeX | RIS

M. Krause, B. Marz, C. Dresbach, M. Petzold:

Electron backscatter diffraction microstructure investigations of electronic materials down to the nanoscale.

doi:10.1109/ESTC.2010.5642809

BibTeX | RIS

C. Dresbach, M. Mittag, M. Petzold:

Elastic properties of bonding wires.

doi:10.1109/ESTC.2010.5642992

BibTeX | RIS

Sandy Bennemann, Christian Dresbach, Georg Lorenz, Lutz Berthold, Matthias Petzold:

Microstructure and mechanical properties of laser ablation cleaned NiP platings for aluminum wire bonding.

doi:10.1109/ESTC.2010.5642852

BibTeX | RIS

Kerstin Nötzold, Christian Dresbach, Jürgen Graf, Bianca Böttge:

Temperature dependent fracture toughness of glass frit bonding layers.

doi:10.1007/s00542-010-1037-5

BibTeX | RIS

2009

C. Dresbach, M. Mittag, M. Petzold, E. Milke, T. Müller:

Mechanical properties and microstructure of heavy aluminum bonding wires for power applications.

URL

BibTeX | RIS

C. Dresbach, G. Lorenz, M. Mittag, M. Petzold, E. Milke, T. Müller:

Local Hardening Behavior of Free Air Balls and Heat Affected Zones of Thermosonic Wire Bond Interconnections.

URL

BibTeX | RIS

Seung-Mo Lee, Eckhard Pippel, Ulrich Gösele, Christian Dresbach, Yong Qin, C. Vinod Chandran, Thomas Bräuniger, Gerd Hause, Mato Knez:

Greatly increased toughness of infiltrated spider silk.

doi:10.1126/science.1168162 PMID

BibTeX | RIS

Seung-Mo Lee, Gregor Grass, Gyeong-Man Kim, Christian Dresbach, Lianbing Zhang, Ulrich Gösele, Mato Knez:

Low-temperature ZnO atomic layer deposition on biotemplates: flexible photocatalytic ZnO structures from eggshell membranes.

doi:10.1039/b820436e PMID

BibTeX | RIS

K. Nötzold, C. Dresbach, J. Graf, B. Böttge:

Temperature dependent fracture toughness of glass frit bonding layers.

URL

BibTeX | RIS

2008

L. Merkle, T. Kaden, M. Sonner, A. Gademann, J. Turki, C. Dresbach, M. Petzold:

Mechanical fatigue properties of heavy aluminium wire bonds for power applications.

doi:10.1109/ESTC.2008.4684554

BibTeX | RIS

Bianca Boettge, Christian Dresbach, Andreas Graff, Matthias Petzold, Joerg Bagdahn:

Mechanical Characterization and Micro Structure Diagnostics of Glass Frit Bonded Interfaces.

doi:10.1149/1.2982898

BibTeX | RIS

2007

C. Dresbach, H. Knoll, J. Schischka, M. Petzold, K. Hosseini, L. Schrapler:

Test Methods for Characterizing the Local Plastic Deformability of Bonding Wires.

doi:10.1109/ESTC.2006.280093

BibTeX | RIS

2006

M. Petzold, C. Dresbach, M. Ebert, J. Bagdahn, M. Wiemer, K. Glien, J. Graf, R. Muller-Fiedler, H. Hofer:

Fracture mechanical life-time investigation of glass-frit bonded MEMS sensors.

doi:10.1109/ITHERM.2006.1645501

BibTeX | RIS

2005

C. Dresbach, A. Krombholz, M. Ebert, J. Bagdahn:

Mechanical properties of glass frit bonded micro packages.

doi:10.1007/s00542-005-0031-9

BibTeX | RIS

M. Ebert, C. Dresbach, A. Krombholz, J. Bagdahn, K. Glien, J. Graf, R. Müller-Fiedler, H. Hofer:

Mechanical Failure Behavior of Glass Frit Bonded Structures.

BibTeX | RIS

Further Information

Informationen zum Ablauf bei Abschlussarbeiten finden Sie im LEA-Kurs AG Dresbach