ReBauVES - resource optimised development of structural elements

Research project at a glance

Funding type

Period

01.02.2015 to 31.01.2018

Project manager at H-BRS

Project Description

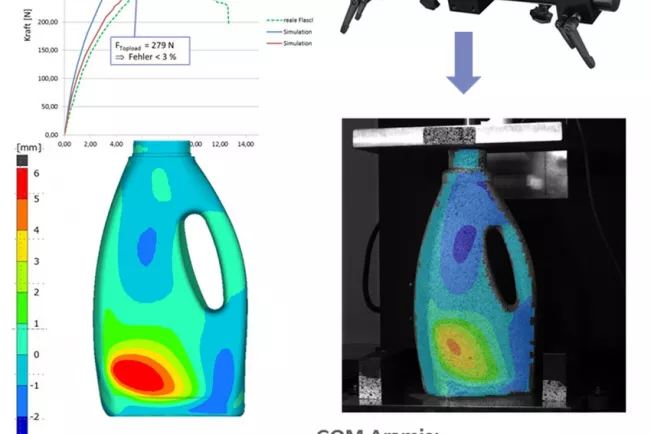

The use of FEM structural analysis for the development of extrusion blow mouldered parts is state of the art. Product properties like stackability can be predicted with high accuracy. Though, it is involving to determine material parameter necessary to give a significant simulation. Due to material stretching during the blow moulding process combined with high cooling rates, the properties of thermoplast materials is influenced significantly. Therefore it is not possible to refer to data from literature; instead, for each material all parameters have to be determined experimentally. Transferring these parameters to other materials or process conditions hardly possible. The reason for this is the lacking basic knowledge on a molecular scale.

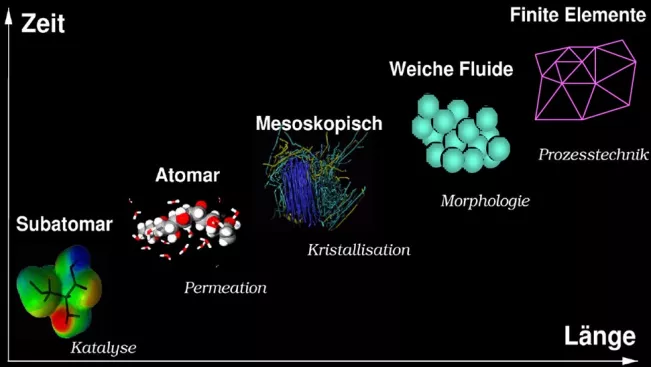

The coupling of already existing macroscopic models with those in micro scale offers new possibilites: Influences of the manufacturing process on the polymers, resulting in changes of the material properties, become clearer when the molecular details are studied. With the help of computer simulation, basic microscopic knowledge can be transferred into macrosopic information.

The main goal is to create a completely process based material model with the help of simulation models on micro scale as well as extensice studies.

Cooperation partners

Sponsors