reTURN - Recycling organic residues and CO2 into fuels

Research project at a glance

Funding type

Period

01.01.2023 to 31.12.2026

Project Description

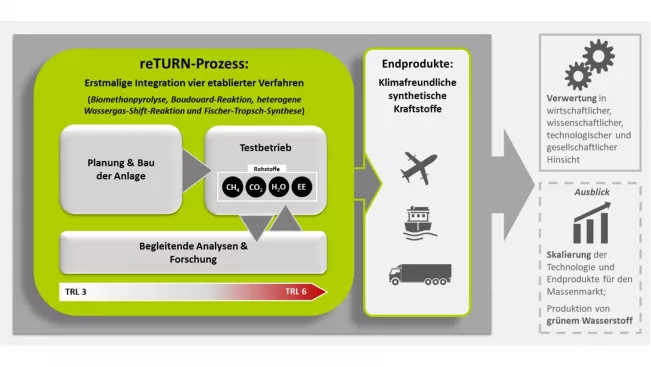

The reTURN project partners are stepping up to revolutionize the transportation sector through sector coupling and to demonstrate a process for producing climate-friendly synthetic fuels at a viable cost. With much higher efficiency than in alternative processes, such as pure power-to-liquid (PtL) processes, high-quality end products (synthetic fuels, green base chemicals) are to be produced from waste CO2. For this purpose, CO2 and CH4 from a biogas plant are used and converted to synthesis gas (carbon monoxide and hydrogen). Methane pyrolysis breaks down the methane in the biogas into its components, producing green gaseous hydrogen and solid carbon. These raw materials form the basis of the reTURN process, which for the first time integrates a total of four already established and proven processes in a novel holistic technology concept up to the production of synthetic fuels: (1) plasma process by means of biomethane pyrolysis, (2) Boudouard reaction, (3) heterogeneous water gas shift (hetWGS) reaction and (4) Fischer-Tropsch synthesis. Exactly this integration and thus the testing of a new technology represents the innovation of reTURN.

Figure 1 presents the concept of reTURN. The central component is the construction and test operation of the plant for the production of synthesis gas and synthetic fuels based on the innovative reTURN process. Depending on the customer and the application, the respective form of the climate-friendly end product can be flexibly determined. Through a targeted site selection, existing infrastructures and partnerships are utilized and local sources for CH4, CO2 as well as H2O are accessed.

The workgroup of Prof. Dr. Stefanie Meilinger is responsible for ongoing scientific monitoring and re-evaluation of the processes to assess their ecological sustainability. This includes a detailed investigation of the CO2 footprint as a measure of global warming potential (GWP) in CO2 equivalents for the overall process and its infrastructure, comparing it to other fuel supply options.

Cooperation partners

Sponsors