Beyond SPAI

Research project at a glance

Departments and Instituts

Funding type

Period

01.04.2016 to 31.05.2020

Project manager at H-BRS

Project Description

Industrial robots could be used with higher efficiency than before due to today's technical improvements. But for the sake of accident prevention they still work almost exclusively "under themselves". People have to be kept out of their working area by means of fences or the working speed of the robots has to be reduced considerably, if people are in danger, for example during robot maintenance.

It would be useful for improved productivity if during the normal work process, heavy parts are precisely positioned by the robot while a worker does complex mounting of components to the heavy part - safely natural!

This approach is called „Smart Production“ within the future project„Industry 4.0“ . In case of the project „beyondSPAI“ the advancement of the Robot-Human-Interaction with regard to the safety. However, this requires a different kind of protective measures compared to those fences mentioned at the beginning. The collaborating robots should become the so-called direct collegues of the human being, being able to think proactively and to react flexibly to the people working next to them.

The project is the continuation of the project "SPAI - safe person detection in the working area of industrial robots by application of an active NIR camera system."

The research project of the Hochschule Bonn-Rhein-Sieg considers both safety of the far and of the critical close-up range directly between humans and the "collegue robot". This requires a multi-level, teethed protection in order to exhaust the efficiency of the collaboration and, at the same time, safeguard the safety of the employees. In order to find a solution, the project group focuses on the intelligent combination of different sensor technologies, especially within the close-up range of the robot.

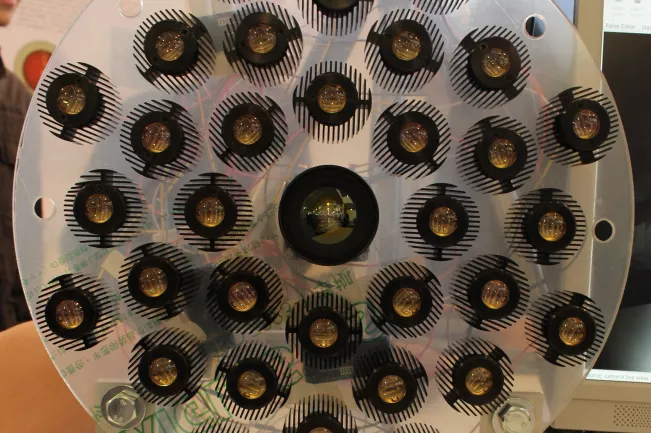

Directly mounted sensors on the robot should clamp a protective zone closely around the moveable parts of the system. On this spot, both optical point sensors directly on the tool of the robot and a net of ultrasound sensors should be applied. Optical sensors make it possible to reliably distinguish the relevant material surfaces and are especially suitable for skin detection due to their special reflecting character within the close-up ultrared area via a so-called " spectral signature". This method allows us to safely detect human skin independently of their color, sex and age. With regard to the reliability of a detection due to color characteristics whithin the visible spectral area, it performs much better. This property can be used especially while handling the tool of the robot, for example to impede the application of a welding tool in the end with an arm or a hand. Together with the ultrasound sensors and possible further sensor types this enables a multiple redundant surveillance of the close-up danger zone directly around the robot.

In a medium-sized distance to the robot a special close-up ultrared camera system is to be applied in order to control a wider protection zone. The camera system is analoguely to the optical sensors for the close-up area in the position to detect skin with a high robustness. In this case, we add special image processing algorithms for the detection of persons by skin information in order to safely detect the silhouette of humans on the picture. For this purpose, this system should be mounted on a controllable mobile chassis, enabling the alignment of the camera to a context-specific critical danger zone. The protection system can identify the information known by programming the robot via the next actions. This way, we are in the position to specifically control areas, in which no people should be found during the next planned movement.

By means of the described sensor technology and applying an intelligent software the industrial robot systems should in the end be in the position to reliably detect when they come too near to a human being and stop eyery dangerous movement for them in time. However, in such a dangerous case, as far as possible not the whole production line should be stopped, but only the concerned "collegue robot" until his sensors show no danger for people in the danger zone any more.

Due to the practical relevance for future production methods the Hochschule was able to win the Institut für Arbeitsschutz der DGUV, the TH Köln and the company K.A. Schmersal GmbH & Co. KG as partners for this project cooperation, whereupon Schmersal takes over 10% of the project costs. But also internally, the Hochschule interdisciplinary cooperates within the departments "Computer Sciences" and "Electrical engineering and Mechanical engineering" in order to be in the position to carry out the research project successfully with the necessary expertise.

Cooperation partners

Sponsors