LignoBau - lignin based polymers for building applications

Research project at a glance

Departments and Instituts

Funding type

Period

01.12.2014 to 30.11.2018

Project manager at H-BRS

Project Description

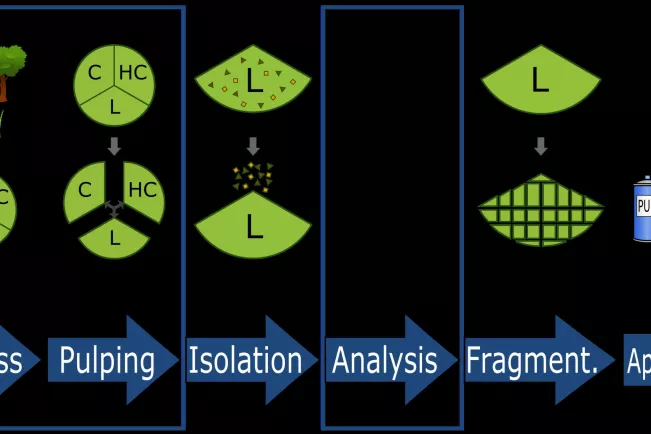

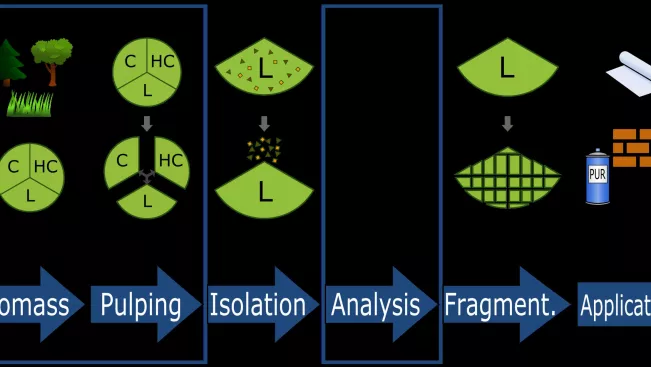

Lignin is one of the most important components of all plants (about 30% in wood), right after cellulose. Worldwide about 50 million tons of techniqually isolated lignins are gained during pulp production but only 2% of it is acutally used.

Aim of this project is to recycle and modify the lignin "waste" so that lignin based polymers can be generated and used for building issues.

About 25% of all synthetic materials are used in the construction sector. Foams are almost exclusively based on fossil sources, e.g. Polystyrene insulants or Polyurethan (PU)-foams. Due to the steady improvement of insulants for office as well as for private buildings, the demand is rising continously. Here, also lignin could play an important role in the future: Mostly used for energetic issues, it could now find application as a mechanical alternative for improved insulations. The distinct adherance properties of lignin can be used to produce lignin based construction material, e.g. for better sound insulation. Moreover, the recycled lignin can be tested as a substituent in glues or binding agents instead of phenol.

Publications

- Hansen B; Schulze M; Kamm B. Qualitative and quantitative analyses of lignins from different LCFbiomasses for using as polymeric compounds. In Analytical techniques for biomass products. Eds. Seidl P, Vaz Jr S. Royal Society of Chemistry (invited contribution in preparation).

- Kamm B, Kamm M, Hirth T, Schulze M, Lignocelluloses Based Chemical Products and Product Family Trees in Biorefineries – Industrial Processes and Products, M. Kamm, B. Kamm, P.C. Gruber, Wiley-VCH, 200

- Hansen B, Kamm B, Schulze M. Characterization of lignin produced from beech wood by Organosolv process. Submitted to ChemSusChem (submission No cssc.201402355), WILEY VCH.

Research associates

Cooperation partners

Sponsors

Dokumente

zum Herunterladen