MatRes - material and resource efficiency for blow moulded parts

Research project at a glance

Departments and Instituts

Funding type

Period

01.07.2010 to 30.11.2013

Project manager at H-BRS

Project Description

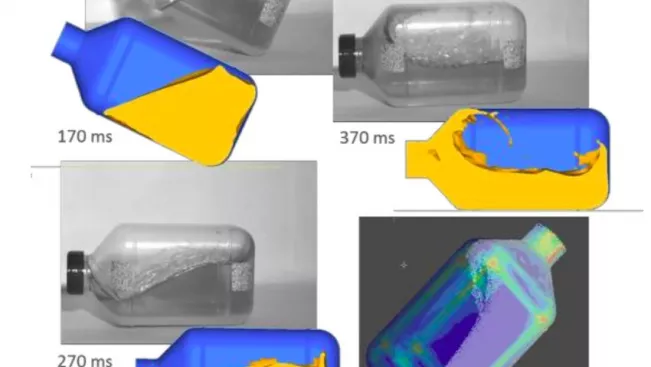

The aim of this project is to improve the efficiency for materials and resources of blow mouldering parts and packaging products below 3 liters. This shall be realised via optimisation of theoretical valuations like the FEM structure analysis. Integral properties can so be foreseen in the stage of development. Nevertheless, it is also necessary to improve the facturing hardware, so that the theoretically calculated thicknesses can be realised.

Not only the development of new simulation methods, for example to simulate filling processes or the pinch-off weld, but also the material properties are in the main focus. The influnce of process parameters such as

- wall thickness

- degree of torsion and degree of orientation

- cooling rate

are investigated and implemented into the simulation models

Research associates

Cooperation partners

Research Assistants

Dokumente

zum Herunterladen