🎓Development of a robust optimisation process for the structural optimisation of blow-moulded plastic hollow bodies, taking into account material quality losses due to an increased proportion of recycled material

Doctoral project at a glance

Keywords

Period

01.01.2023 to 01.01.2028

Project Description

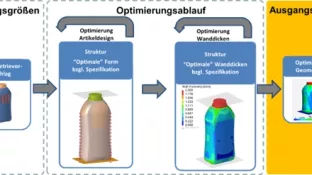

Plastic products are widely used in many industries and can be manufactured particularly cost-effectively using extrusion blow moulding. However, this results in process-related variations in wall thickness, which are exacerbated by uncertainties in the manufacturing process and in the material properties - especially when using recycled materials. In order to develop efficient and resource-saving products, both the geometry and the wall thickness distribution must be optimised. The aim of the doctoral project is to develop a product that is as light and robust as possible and that functions reliably despite variations in wall thickness.

Contact Points

Graduierteninstitut: Contact

Campus

Sankt Augustin

Room

F 427 , F 425, F 423

Opening hours

Mon-Fr 9.00 am-1.00 pm call us, send an e-mail or make an appointment for individual counselingfor