Department of Engineering and Communication

Prof. Dr Dirk Reith

Computational Science and Engineering /Managing Director of the TREE Institute/Presidential commissioner for institutional research co-operations/Faculty Advisor BRS Motorsport

Unit

Department of Engineering and Communication, Institute of Technology, Resource and Energy-efficient Engineering (TREE)

Research fields

- Molecular Simulation of Soft Matter (Lubricants, (Bio-)Polymers, Solvents), including Method Development

- Computational Fluid Dynamics (Lattice-Boltzmann-Method), Fluid-Structure-Interaction

- Digital Twin-4-Multiphysics Lab (together with Fraunhofer IZB (SCAI and IAIS) and Dr. Reinold Hagen Stiftung)

- Modern Teaching Methods in Engineering Education (PBL, Peer-Mentoring, Employability)

- ORCID: https://orcid.org/0000-0003-1480-6745

Location

Sankt Augustin

Room

B 223

Address

Grantham-Allee 20

53757 Sankt Augustin

Telephone

+49 2241 865 9678Profile

Fields of Expertise:

- Polymers, Solvents and Ionic Liquids/Lubricants

- Force Field optimization of molecular models via semi-automatic workflow tools

- Algorithms: Iterative Boltzmann-Inversion (IBI), Reversed Non-Equilibrium Molecular Dynamics (RNEMD), Semi-Lagrangian Lattice-Boltzmann-Methode (SLLBM)

- Software-Products - CompChem: Wolf2Pack, GROW, COFFE und ESPResSo++

- Software-Products - Lattice-Boltzmann: NATriuM, Lettuce

- Hobby: General sales forecast models for automobile markets and their analysis

Teaching:

- MB Master - Classical Mechanics (Theoretical Physics 1)

- MB Master - Technical Mechanics 4 (Advanced Dynamics)

- MB Bachelor E3 - Technical Mechanics 3 (Dynamics)

- MB Bachelor A4P und NI D4 - Modeling and Simulation for Engineers 1

- MB Bachelor A6P - Modeling and Simulation for Engineers 2

- Bachelor E4/6 Elective - Sustainable Race Car Design Aspects

- Bachelor A7 Elective - Cost- and Production Management Formula Student

- Bachelor P3/4/6 Projekts, z.B. Energy Storage Competition, Self-made Hexacopter Construction

Curriculum vitae

1992 - 1998 Studies (Physics, Mathematics, Higher Teacher Training), Johannes-Gutenberg Universität Mainz and Universität Uppsala, Sweden

1998 Visiting Scientist, Research School of Chemistry, Australian National University, Canberra, Australien

1999 - 2002 Research assistant (doctorate/post-doc), Max-Planck-Institut für Polymerforschung, Mainz

2002 - 2006 Business Analyst / IT Project Manager, Central Sales Department, DaimlerChrysler AG, Stuttgart

2006 - 2012 Group Leader "Computational Chemical Engineering", Fraunhofer SCAI, Schloss Birlinghoven, Sankt Augustin

Herbst 2017 Visiting Professor, Department of Chemical Engineering, University of California, Davis, USA

Current:

Since 09/2012 Professor of Basic Engineering, H-BRS.

Since 09/2012 Senior Consultant, Advance Research & Development - Business Areas

Multiphysics and High Performance Computing, Fraunhofer Institut SCAI, Sankt Augustin

Since 03/2014 Research Professor, H-BRS

Since 01/2016 Founding Director at the Institute for Technology, Resource Efficiency and Energy Efficiency (TREE) of the H-BRS

Memberships

- Senior Consultant @Multiphysics Dept, Fraunhofer SCAI

- Board Member @Department Resources and Sustainability, Doctoral College NRW

- American Institute of Chemical Engineers (AIChE)

- American Chemical Society (ACS)

- German Physical Society (DPG)

- DECHEMA/VDI Initiative "ProcessNet"

- The Association of German Engineers (VDI)

- Institute of Visual Computing (IVC) @HBRS

- Centre for Teaching Development and Innovation (ZIEL) @HBRS

- Scientific Director, Institute for Technology, Resource- and Energy-efficient Engineering (TREE)

- Presidential commissioner for co-operations with non-university research institutions

- Faculty Advisor, BRS Motorsport Team (Formula Student)

- Member, H-BRS Senate

- Member, Commission for Research and Transfer

Research Projects

Ageing processes of plastics are better understood and integrated into the product development of blow-moulded plastic hollow bodies - for more durable and resource-saving packaging solutions.

Project management at the H-BRS

Prof. Dr Corinna Thomser Prof. Dr Olaf Bruch Prof. Dr Mandy Gieler-Großgarten Prof. Dr Dirk Reith Prof. Dr Johannes Steinhaus Dr Esther van DorpOpenSKIZZE: Open source development tools for urban development: climate impact adaptation with cooperative AI-supported decision-making processes. As an open source AI assistant, OpenSKIZZE is intended to transfer the findings from climate models into concrete construction projects. This system is intended to involve all stakeholders in the process at an early stage and inform them about the effects of their decisions on the local urban climate.

Project management at the H-BRS

Dr Alexander Hagg Prof. Dr Dirk ReithResearchers from all disciplines are confronted with increasingly large amounts of data. The newly founded Rhine-Ruhr Center for data literacy (DKZ.2R) has set itself the goal of supporting and promoting researchers from a variety of research disciplines with regard to increasingly complex data analysis, data management and high-performance computing.

Project management at the H-BRS

Prof. Dr Sebastian Houben Prof. Dr Dirk ReithBio-chemical research is increasingly dependent on accurate computer modelling and analysis. This field of research is by its very nature highly interdisciplinary, as basic physical laws must be implemented algorithmically in order to make relevant contributions in life science applications. The project and the associated initiative UMMBAS bundles the strong cross-disciplinary expertise at the H-BRS in method development, visualisation and the application of computer-based procedures for deciphering material science and biochemical issues.

Project management at the H-BRS

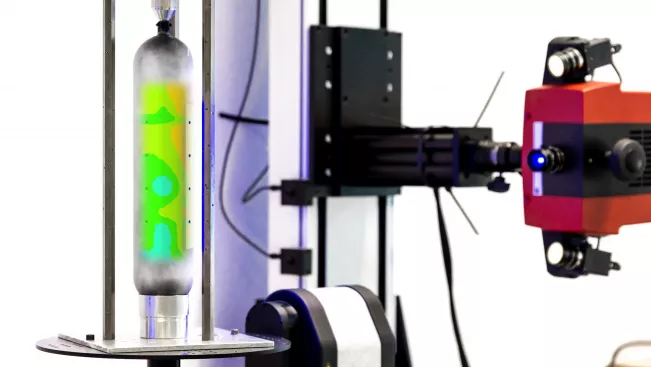

Prof. Dr Matthias PrellerThe "Digital Twin-4-Multiphysics Lab" (DT4MP) focuses on urban digital twins (UDTs) and multiphysics twins for industry, treating both areas equally and synergistically. By integrating real-time data and advanced simulations, DT4MP enhances urban processes, infrastructures, and industrial production efficiency. Combining AI and machine learning, the lab provides services like data analysis and virtual testing for SMEs and larger companies. Founded by leading institutes, DT4MP drives digitalization research in urban and industrial contexts.

Project management at the H-BRS

Prof. Dr Sebastian Houben Prof. Dr Dirk Reith Dr Alexander HaggIn modern society, plastic packaging fulfills important functions for consumers and industry and is indispensable in everyday life: easy and inexpensive to produce in large quantities, it significantly simplifies handling during transport and storage and extends the shelf life of food up to three times.

Project management at the H-BRS

Prof. Dr Christian Dresbach Dr Esther van DorpThe institute TREE operates the TREE-Energy Lab (TRE3L) in the university's Center of Applied Research (ZAF) with it's industrial partners GKN Driveline and GKN Sinter Metals. In the three sub-labs Powder Fabrication-Lab, Mobility-Lab and Hydrogen-Lab the three partners work on innovative techniques in powder metallurgy and recent topics of environment friendly mobility and energy-efficiency. These labs are supported by a Simulation-Lab.

Project management at the H-BRS

Prof. Dr Alexander Asteroth Prof. Dr Tanja Clees Prof. Dr Dirk ReithBonn-Rhein-Sieg University of Applied Sciences has adapted its existing transfer instruments to the changing demands and requirements of business and needs of business, society and science and developed new suitable transfer mechanisms. The project was funded by the federal-state initiative "Innovative University".

The development of sustainable electromobility is one of the social challenges our time, which is considered in the research project eTa. The energy efficiency of vehicles is addressed in aerodynamic projects and optimized operating strategies. In particular, non-classic vehicle concepts are in focus. Alternative mobility concepts based on non-fossil fuels need new supply structures. The optimized expansion of the loading infrastructure is therefore another issue. But even the best mobility concept is useless if it is not accepted by society and implemented by politics and business. Therefore, acceptance questions are a central element of eTa, which will be further developed. The following areas are addressed primarily by the need to reduce energy consumption: Efficiency of the vehicles Alternative mobility concepts Efficiency of mobility concepts Technical acceptance In particular, these are questions which arise only from the combined consideration of these subject areas and are usually not fully answered in classical manner. Examples of this are optimization of hybrid controls for muscle-electric hybrid light vehicles and study of the aerodynamics of ultralight vehicles where results of the classic wind tunnel tests often do not correspond to the results of the practice. Other topics that we are dealing with are predictive operational strategies for electric combustion hybrid vehicles and loss optimization, optimization of multi-stage placement of charging stations, acceptance of alternative mobility concepts.

Project management at the H-BRS

Prof. Dr Alexander AsterothWithin the framework of the NRW-Ghana Partnership and the funding program "NRW-Partnerships for the Promotion of Technical Universities in Ghana", the Ministry of Innovation, Economy and Research (MIWF) has been funding the university partnership project "Partnership for Applied Sciences - PASS" between the Bonn-Rhein-Sieg University of Applied Sciences (consortium leader), the Cologne University of Applied Sciences, the International University of Applied Sciences Bad Honnef and the two Ghanaian universities Kumasi Technical University and Cape Coast Technical University through the German Academic Exchange Service (DAAD) since 2017.

As part of the NRW-Ghana Partnership and the funding programme "NRW Partnerships for the Promotion of Technical Universities in Ghana", the Ministry of Innovation, Economics and Research (MIWF) has been funding the university partnership project "Partnership for Applied Sciences - PASS" between Hochschule Bonn-Rhein-Sieg University of Applied Sciences (consortium leader), Cologne University of Applied Sciences, Bad Honnef International University of Applied Sciences and the two Ghanaian universities Kumasi Technical University and Cape Coast Technical University through the German Academic Exchange Service (DAAD) since 2017. The project has a duration of four years.

Publications

Complete List:

Google Scholar or ResearchGate

Representative Selection:

R. Strickstrock, M. Hülsmann, D. Reith, K.N. Kirschner: "Optimizing Lennard-Jones parameters by coupling single molecule and ensemble target data", Comp. Phys. Comm. 108285 (2022). DOI: 10.1016/j.cpc.2022.108285

P. Carbone, R. Faller, H.J. Qian, D. Reith: "Tailor-made approaches on use of multiscale modeling for research on soft materials–capabilities, restrictions and future possibilities", Soft Materials 18(2-3), 111-112 (2020). DOI: 10.1080/1539445X.2020.1746337

D. Grommes, M.R. Schenk, O. Bruch, D. Reith: "", Polymers 13 (24), 4466 (2021). DOI: 10.3390/polym13244466

D. Wilde, A. Krämer, D. Reith, H. Foysi: "Semi-Lagrangian lattice Boltzmann method for compressible flows", Physical Review E 101(5), 053306 (2020). DOI: 10.1103/PhysRevE.101.053306

D. Reith, C. Blume, M. Grein, T. Haedecke, D. Könemann, M. Malschützky: "Sustaining complex projects by linking in- and off-curriculum elements: The BRSU Racing Engineer Certificate", 2020 IEEE Global Engineering Education Conference (EDUCON), 905-912. DOI: 10.1109/EDUCON45650.2020.9125147

C. Schmahl, W. Hildebrandt, D. Reith: "Efficiency Improvements of Electrical and Conventional Vehicles" MTZ worldwide 79(4), 38-43, Springer (2018). DOI: 10.1007/s38313-018-0004-x

M. Hülsmann, K. N. Kirschner, A. Krämer, D. D. Heinrich, O. Krämer-Fuhrmann, D. Reith: „Optimizing Molecular Models Through Force Field Parameterization via the Effcient Combination of Modular Program Packages“, in “Foundations of Molecular Modeling and Simulation”, 53-77, Springer (2016). DOI: 10.1007/978-981-10-1128-3_4

A.A. Tietze, F. Bordusa, R. Giernoth, D. Imhof, T. Lenzer, A. Maaß, C. Mrestani-Klaus, I. Neundorf, K. Oum, D. Reith, A. Stark, "On the nature of interactions between ionic liquids and small amino acid-based biomolecules", Chem. Phys. Chem. 14, 4044-64 (2013), DOI: 10.1002/cphc.201300736

Links

Further links