🎓Ageing modelling of large blow-moulded containers for an increased sustainability in product life span

Doctoral project at a glance

Keywords

Period

17.05.2024 to 17.05.2029

Project Description

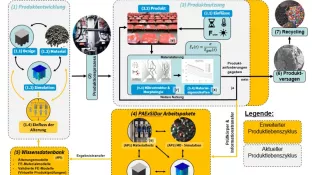

The aim of the doctoral project is to better understand the ageing of large-volume plastic packaging - particularly extrusion blow-moulded polyethylene - and to be able to predict its product life more reliably. At the centre of this is the development of computer-aided models that depict the complex changes in material properties under real conditions of use. With the help of accelerated ageing tests in the laboratory and modern simulation techniques such as the finite element method (FEM), both chemical changes in the plastic (e.g. due to UV radiation and heat) and physical effects such as residual stresses from production are to be analysed. The combination of experimental and numerical methods should make it possible to precisely predict ageing processes and optimise future products in a targeted manner. The project thus contributes to sustainable product development and the reduction of plastic waste through longer product lives.

Cooperation partners

The doctoral programme is carried out with the Doctoral College NRW (PK NRW).

Anlaufstellen

Graduierteninstitut: Contact

Campus

Sankt Augustin

Room

F 427 , F 425, F 423

Opening hours

Mon-Fr 9.00 am-1.00 pm call us, send an e-mail or make an appointment for individual counselingfor