WireLife - Lifetime of new aluminum wires of power electronics

Research project at a glance

Funding type

Period

01.08.2022 to 31.01.2027

Project Description

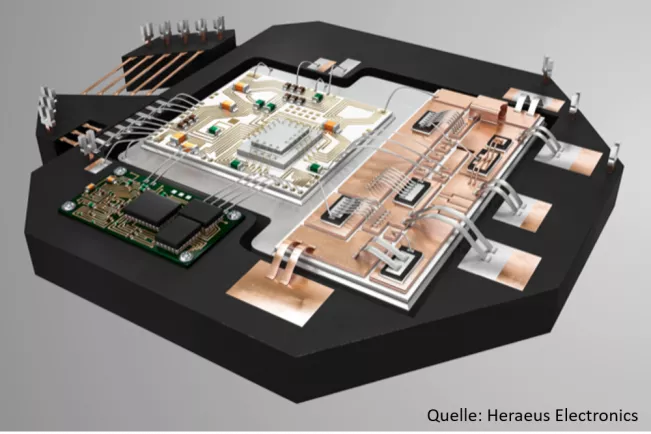

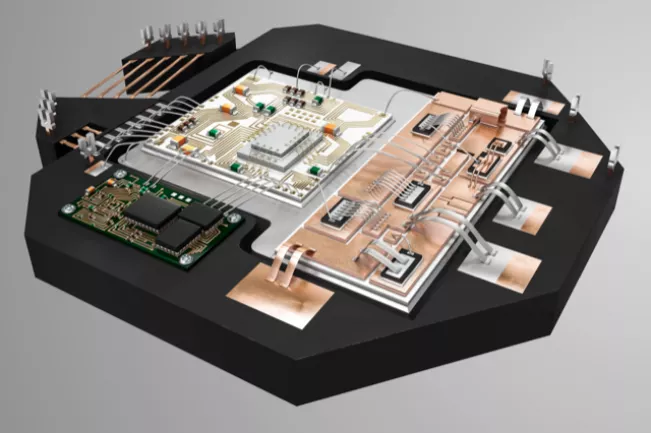

For the transmission of electrical power in control units and power electronics modules, wire or ribbon bonds made of aluminum are mostly used. Aluminum is used where large energy transfers take place via bonded connections, as it can withstand twice as high a current load as copper in relation to its specific weight. Since the connection points of the wires and ribbons are usually located on substrates made of different materials and the components are frequently exposed to external temperature differences, cracks can form in the material during operation and lead to complete failure of the component, which cannot be remedied by simple design modifications.

In WireLife, computer models are to be developed and backed up with experimental data that will make it possible to reduce the manufacturing costs of wires and ribbons without at the same time reducing the performance of the connections. Furthermore, the development of new high-performance alloys and their market introduction will be supported. For this purpose, numerical prediction models of the standard manufacturing process as well as alternative manufacturing routes will be developed and validated with experimental investigations on a commercial aluminum alloy. In addition, detailed lifetime models will be developed taking into account temperature-dependent material properties as well as microstructure-based anisotropy and, if necessary, crystal plasticity. Hereby, new alloy variants with better temperature stability and conductivity will be investigated and evaluated with respect to their applicability in power electronics. The industrial applicability will be verified by bonding tests and application-related electrical load tests.

Publications

Cooperation partners

Sponsors

The project WireLife - Lifetime of new aluminum wires for power electronics (FKZ 13FH544KX0) is funded by the German Federal Ministry of Education and Research under the Research at Universities of Applied Sciences funding program.

Links

Weiterführende Links