Research at the university

Research Database: Projects

Forschungsprojekte (247)

Humans are able to come up with plans to achieve their goals, and to adapt them to changes in their environment, finding fixes, alternatives and taking advantages of opportunities without much deliberation. Despite decades of research, artificial agents, such as robots, are not as robust or as flexible. If we look at how we manage to get things done despite the ever-changing environments and our own lack of omniscience we find that this is most often accomplished by making substitutions for missing or unavailable objects and making assumptions about objects for which we have limited information. Enabling service robots, operating in domestic environments to use these two techniques to support human users is the aim of the work of doctoral student IMAN AWAAD.

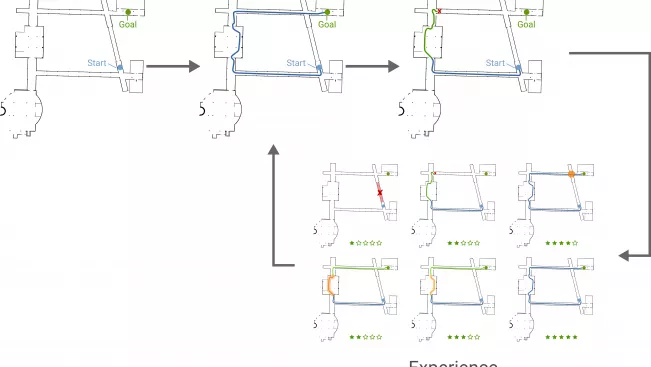

In long-term missions, robots repeat their programmed tasks over and over again, creating new plans each time. One of PhD student Argentina Ortega's research goals is to investigate how robots can improve their planning by using information from their previous runs. From this information, she creates experience models so that robots can reuse their previous plans in an optimised form. This reduces deployment costs while increasing transparency, explainability and system throughput.

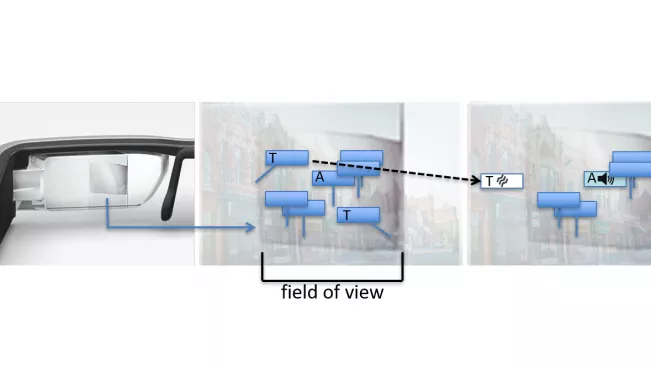

Data glasses are glasses in whose field of vision all imaginable information is displayed visually at the same time. However, even modern data glasses only have a very limited field of vision. Unwanted side effects such as distortion, incorrect depth interpretation or poor legibility of information are the result - especially with increasing information density. At H-BRS, common interdisciplinary view management methods are researched and improved. For example, part of the visual digital information is to be converted into audio and vibration stimuli. Alexander Marquardt's focus is on the design, development and technical implementation of this novel, multisensory information supply. His goal is to reduce visual complexity. It also aims to draw the user's attention in the most intuitive way possible to the information that is of particular interest to him or her.

Force fields have a very large influence on the simulation results of molecules and are the subject of Robin Strickstrock's PhD. The main focus of his research is the (further) development of an automated, algorithm-driven optimisation of the force field parameters, which enables the computer simulations to reproduce or predict properties of new substances on both a molecular and macroscopic level.

In recent years, the collective participation of citizens has increasingly found its way into the German health care system in order to make health policy decisions that better meet the needs of patients. Because of the challenges in the implementation of collective participation as well as the ongoing discussion about the democratic deficit in the German health care system, PhD student SANDRA WRZEZIONO examined the understanding of democracy of citizens by means of qualitative interviews. The project aims to shed more light on the implications for the future design of institutionalized citizen participation.

In recent years, 3D cameras based on the time-of-flight method - also driven by the use in smartphones - have increasingly found their way into our everyday lives. The possible applications of this technology are immense, be it for automatic environment detection in the automotive sector, security and automation functions in robotics, tasks of automatic area monitoring, biometric problems or even the contactless control of technical devices. The aim of the research work of PhD candidate MARKUS ROHDE is to expand the application areas of such 3D cameras. For example, the range for outdoor applications, which is currently limited to about 10 meters, is to be extended to more than 20 meters. For this purpose, innovative infrared laser illuminations are being developed and approaches to signal processing close to the sensor are being researched.

The ongoing digitalisation and introduction of new information systems in everyday working life means that ever larger amounts of personal data of employees are processed by their employers. This development is particularly problematic with regard to employee data protection when employees have neither sufficient knowledge nor control over the processing and thus the right to informational self-determination as a fundamental element of human dignity is threatened. To compensate for the lack of knowledge and skills in exercising the right to privacy at the workplace, PhD candidate JAN TOLSDORF is designing and testing an assistance system in the form of a "privacy dashboard" for everyday work. For its prototypical implementation, design guidelines are to be derived from the mental models and privacy perceptions of employees, with the help of which data processing and data flows in the work environment can be prepared in an understandable way, sensitised to possible infringements of privacy and options for intervention can be shown, so that employees become capable of acting.

AHMAD DRAK develops a flying robot system that is capable of efficiently exploring the ever-changing environment in which it moves. The result is a wealth of useful information that the system is designed to learn from and optimize. Firstly, it decreases the time the robot takes to explore its environment, and secondly, it reduces the energy consumption of the robot system.

In our society, technology is still rather associated with masculinity. There have hardly been any studies on the relationship between visual technology communication and gender in Germany so far. In the first phase of her research, doctoral student Juliane Orth is therefore planning an inventory analysis (image content analysis) of current media images that depict people (in action) with technology. In addition to daily newspapers such as the FAZ, trade journals such as the Technology Review will also be examined. In a second step, the impact of existing and alternative media images will be evaluated by interviews.

Architectural journalism is considered to be a comparably unexplored subject in academic journalism. While there are plenty of empirical studies on journalistic genres such as politics, science and technology journalism, there are few findings on architecture journalism. Yet architecture plays no less important a role in the overall social context than politics and economics. This becomes clear in urban planning and development, new housing concepts and public building projects. Doctoral student Patrycja Muc is therefore conducting a content analysis of how German daily newspaper editorial offices report on architecture. In addition, guided expert interviews with architects and journalists will shed light on the assessment of the relevance of architectural topics by both actors.

Contact Points

Centre for Science and Technology Transfer (ZWT)

Room

F 405

Vice President Research and Transfer

Campus

Sankt Augustin